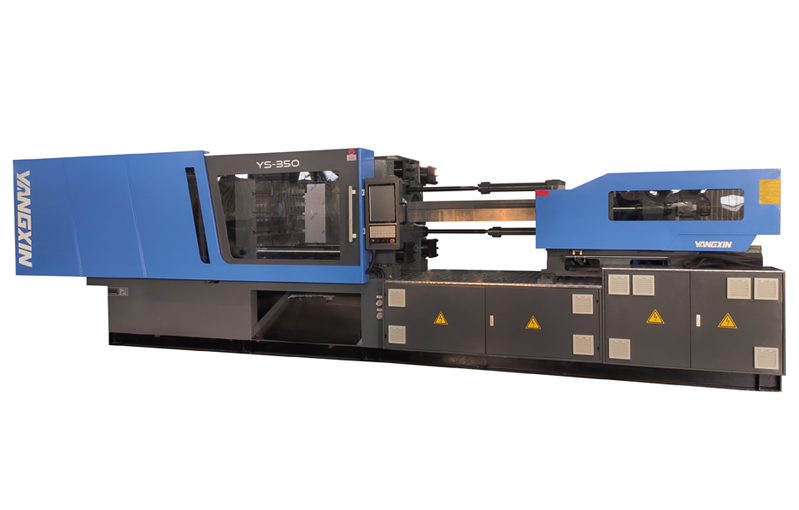

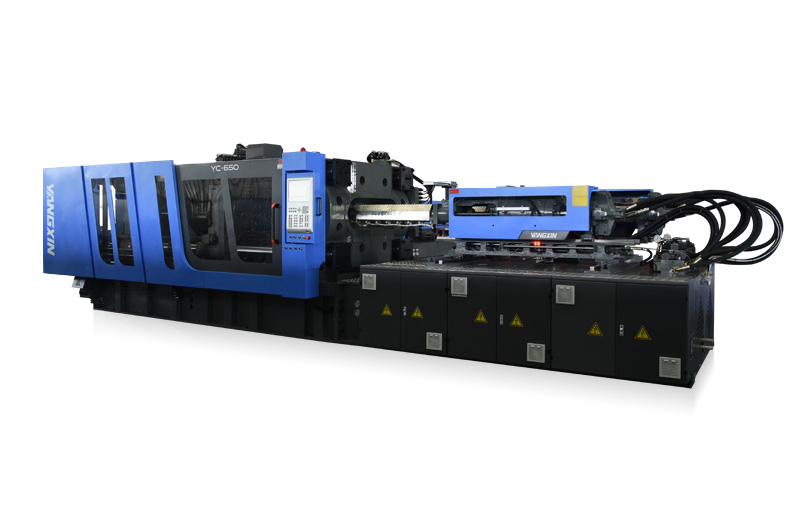

Servo energy injection molding machine

Model number: YX-110

Views:

Support hotline:86-752-6833832

Detailed description

HIGH PERFORMANCE SERVO MOTOR System

◆ YangXin Thermosetting Machine owned precision, fast stale, energy saving and other advantages. The structural design combined with thermosetting forming characteristics for rational design.

◆ Thes thermosetting machines selected the special screw barrel sith corrosion-resistant and wear-resistant material. Special processing and treatment suited thermosetting materials and heat curing through mold temperature controller.

Horizontal thermosetting machine be suitable range

| Suitable range | DAP, Bakelite powder, BMC, Urea and the others suitable materials |

| Clamping Force | 60~320 tons |

| Shot weight range | 107-1489 grams |

| Thermosetting screw barrel | Thermosetting raw materials, mould Temp. Controller and suit for all of thermosetting raw materials (Bakelite material) |

| Horizontal thermosetting machine | Productions can drop down automatically |

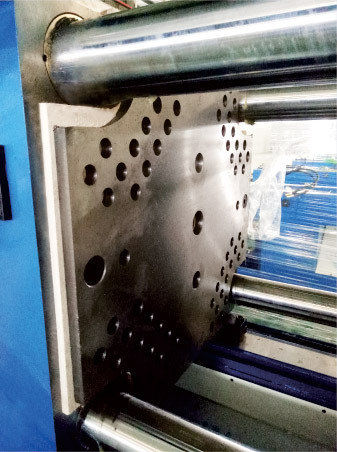

| Sandwich mould platen design | Including heat cutting the hot & cold platen - Glass fiber platen / Asbestos platen. To makesure heater of mould caused machine` s short life or the other unstable problem and unnecessary power waste |

| Addition equipment | Mould temperature controller (offer the curing through mold temperature controller) |

PRODUCT APPLICATION

Be used for a variety of thermosetting (Bakelite material) Bakelite, Tablweare, Hand wheel, Bakelite handle, cutlery, panhandle, Pot ears, Knife handle, Bakelite knob, Switch, Oven accessories, Termials, End button, Meter accessories, Meter shell and etc.

CHARCTERISTICS OF HORIZONTAL THERMOSETTING INJECTION MOLDING MACHINE

◆ Low pressure safe mode: Unique design of zero pressure slow speed off mode thchnology. Protect personal safety. Excellent leader in thermosetting industry.

◆ Automatic fault display and adjust the detection easily.

◆ CPU Controller was from Taiwan. Hydraulic pump & parts selected famous brand for quiet, sophisticated, quick and durable.

◆ Multi-stage injection pressure, injection speed, back pressure without paragraph adjustment suited precision platic parts molding.

◆ Ejector by hydraulic cylinder.

ADVANTAGES

◆ Safe, energy saving, stable, efficient, energy saving and professional after-sales service.MOLD CLAMPING UNIT

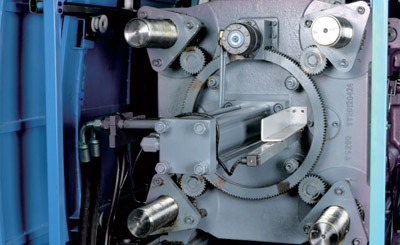

High Precision

A hydrauilc motor drives a planetary gear to ensure perfect and rigid mold heght adjustment.

High rigidity

Optimized template design, improve the rigidity and precision of mold open/closing.

High response

Increase the speed and saves power from 20%~50% depending upon the molding.INJECTION UNIT

Improved the precision of the machine and prolong the service life of the machine greatly reduced the consumption! In view of different material and applications we supply variety of screw and barrel for customer choice.

High precision

Injection unit adopts linear guide rail built-in carriage cylinder, and integral casting support, thus enhence its rigidity, and make the compactstructure.

High stability

Double-carriage cylinder is adopted to ensure stable injectionCONTROL SYSTEM:

The controller is adopting 400M high spdde CPU, which can equip with semiclosure or fully closed system. Plus personality graphic operation interface, curve online testing function and central network connection management. Pmple SPC quality management interface, it is absolutely the best tool to make profit. Equipped with six stages injection, three stages holding pressure, twostages suck back and the holding pressure potittion switching controls etc, can flexibly adust according to different products. Precise injectionend and holding pressure position switching practice high precistion andhigh stability injection function abopt lineal electrical ruler, precisionreaches 0.01mm, which can accurately control injection strok, it canrecord and display simultaneously samping temperature curve during continuous production process, injection and holding pressure switchingpoint and hooding pressure finishing point. Having the function of historical curve allocation, its precision can reach ±1℃. it also has temperature abnormal & electrical wire disconnection alarmfunction, which is able to control the barrel temp-erature accurately. Screwlow temperature staring protection (cold start) can be prevent screw from damagae accidentally, adjustable preheat temperature keeping and barrel auto heating function, which can arbitrarily set cleaning.

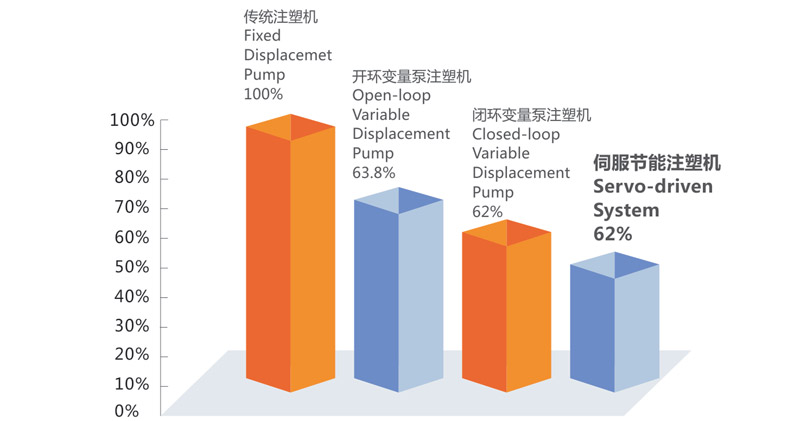

Equipped with six stages injection, three stages holding pressure, twostages suck back and the holding pressure potittion switching controls etc, can flexibly adust according to different products. Precise injectionend and holding pressure position switching practice high precistion andhigh stability injection function abopt lineal electrical ruler, precisionreaches 0.01mm, which can accurately control injection strok, it canrecord and display simultaneously samping temperature curve during continuous production process, injection and holding pressure switchingpoint and hooding pressure finishing point. Having the function of historical curve allocation, its precision can reach ±1℃. it also has temperature abnormal & electrical wire disconnection alarmfunction, which is able to control the barrel temp-erature accurately. Screwlow temperature staring protection (cold start) can be prevent screw from damagae accidentally, adjustable preheat temperature keeping and barrel auto heating function, which can arbitrarily set cleaning.COMPARISON OF POWER CONSUMPTION

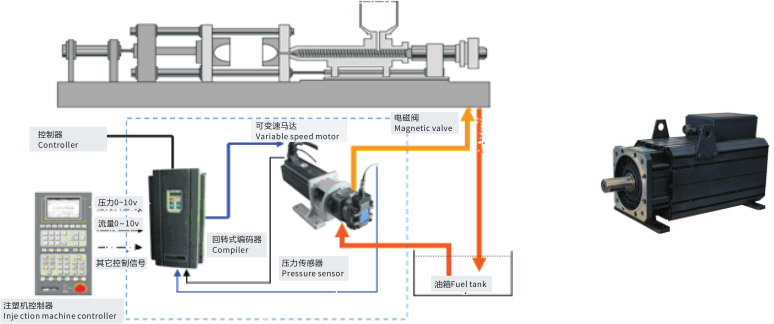

DRIVE TECHNOLOGY

Spsystem consist of variable pump & variable speed motor flow (speed) control/ pressure control Servo Motor

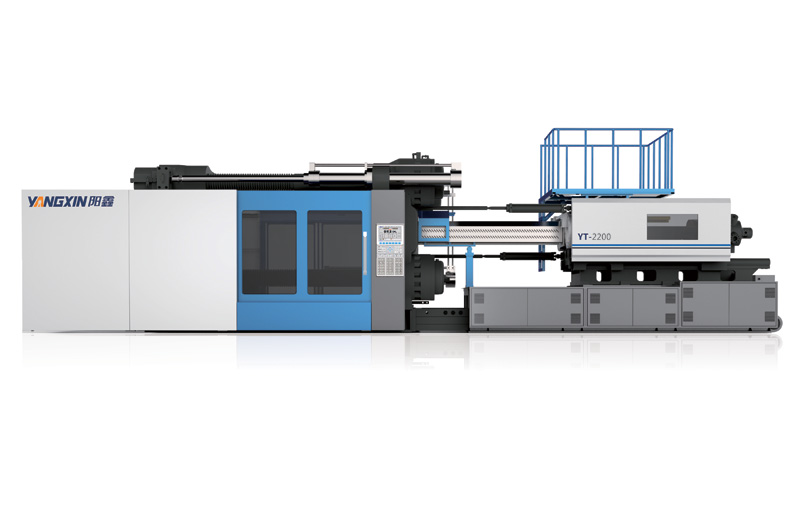

TECHNICAL PARAMETERS

| Project | Unit | YT-2200 | ||

| Injection Unit | Screw diameter | mm | Φ36 | Φ40 |

| Theoretical shot weight | cm3 | 173 | 214 | |

| Shot weight of injection (ps) | gram | 208 | 258 | |

| ozs | 7.3 | 9.0 | ||

| Injection pressure | kg/cm2 | 2204 | 1785 | |

| Injection velocity | cm3/sec | 83 | 102 | |

| Clamping Unit | Mould clamping force | metrictons | 110 | |

| Mould clamping stroke | mm | 350 | ||

| Mould thickness | mm | 110-440 | ||

| Min mould thickness | mm | 255*220 | ||

| Distance between tie bar | mm | 390*340 | ||

| Mould platen (hxv) | mm | 590*540 | ||

| Ejector stroke | mm | 90 | ||

| Electrical Equipment | Max. Motor power | kw | 9.4 | |

| Temp controller | (range)set | (0-400 ℃)*4 | ||

| Others | Dimension | mm | 4800*1100*1800 | |

| Oil tank capacity | liter | 230 | ||

| Machine weight | metric tons | 4.2 | ||

| System pressure | kg/cm2 | 140 | ||

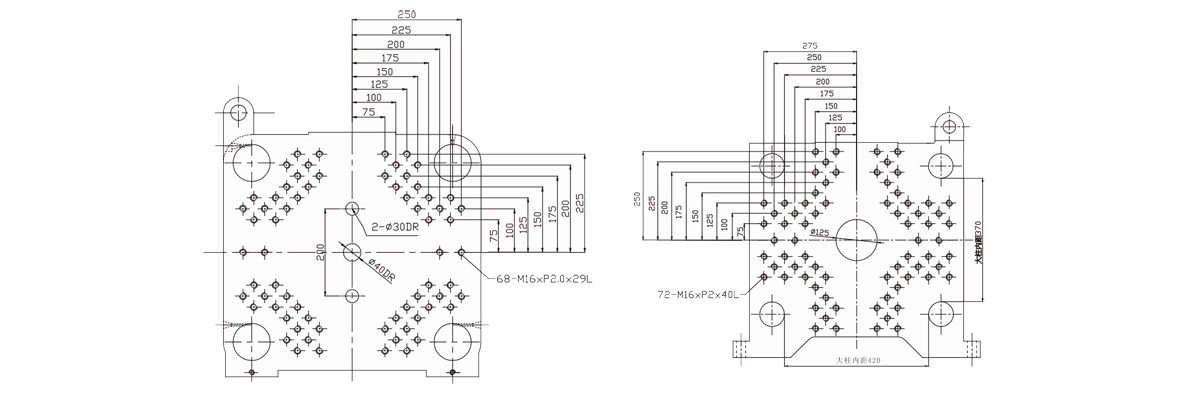

| Platen dimensions |  |

|||

Note: The output of this product parameter is calculated according to the specific gravity of polystyrene of 1.05, assuming an efficiency of 0.88. As the product is continuously researched and improved, the design changes are subject to change without notice.

Next: Servo energy injection molding machinePrevious: First page