Detailed description

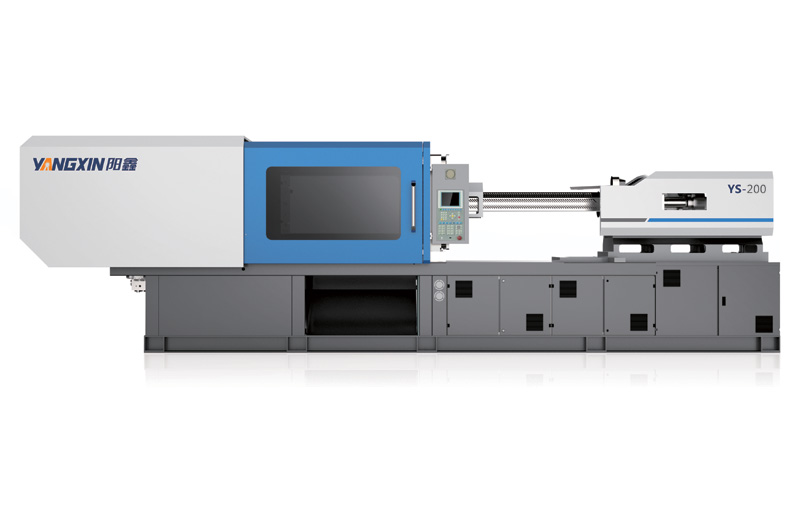

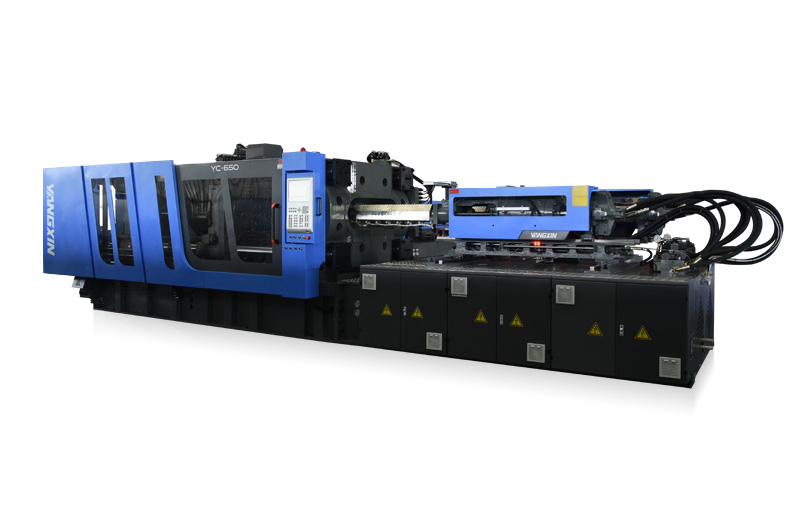

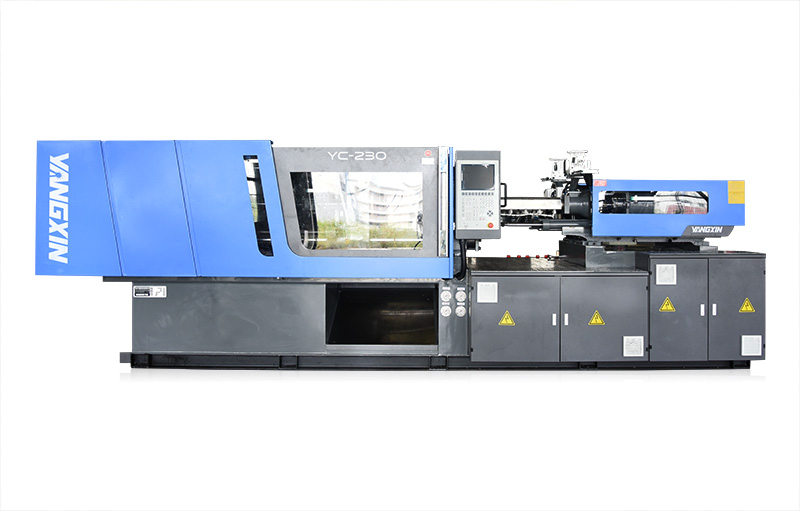

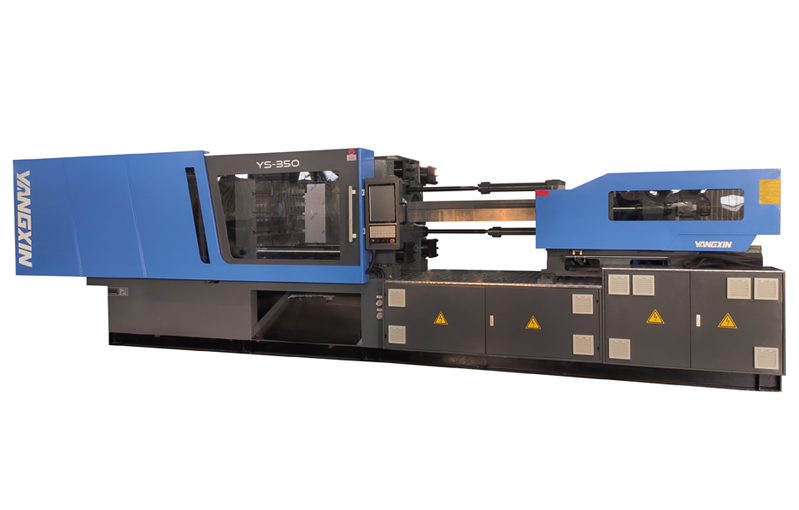

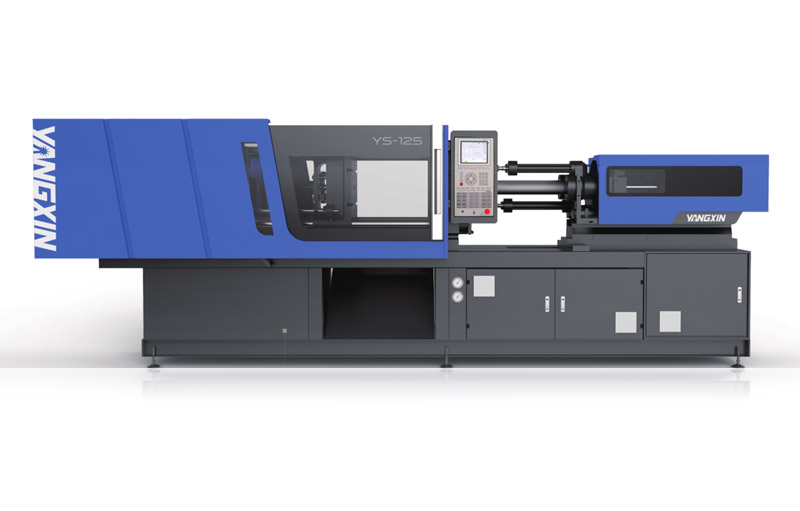

YS series servo energy-saving injection molding machine

Precise clamping system, outstanding efficiency, efficient servo drive, all meet all requirements. Focus on customer products, provide al complete set of technical solutions for customers, and create better investiment returns and customer experience for global customers.MOLD CLAMPING UNIT

Mold opening & closing with 4 stages control, ejecting with 2 stages control. Clamping and ejection are by liner tranducer. Its precision can reach 0.01mm, and contrlo the clam-ping and ejection stroke route accurately. Ejector have function of vibration ejection, ejection atop, multiple ejection pressure and speed of ejection can piecewise set by computer Equipped with high precision low pressure mold closing protection it can be set directly by monitor, low pressure result is perfect. Toggle is used by auto lubrication system, lubrication setting can be operated monitored on the panel directly. And it owns itself lubrication failure alarm function to ensure the machine operating normally.

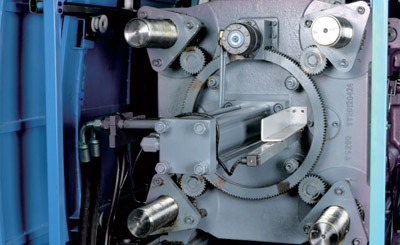

High Precision

A hydraulic motor drives a planetary gear to ensure perfect and rigid mold height adjustment.

High rigidity

The optimized design on rigidity mold platen improve the precision of the product.

High response

Increase the speed and saves power form 20%~50% depending upon the molding.

INJECTION UNIT

Improved the precision of the machine and prolong the service life of the machine greatly reduced the consumption!In view of different material and applications we supply variety of screw and barrel for customer choice.

High precision

Injection unit adopts linear guide rail built-in carriage cylinder, and integral casting support, thus enhence its rigidity, and make the compact structure.

High stability

Double-carriage cylinder is adopted to ensure stable injection.

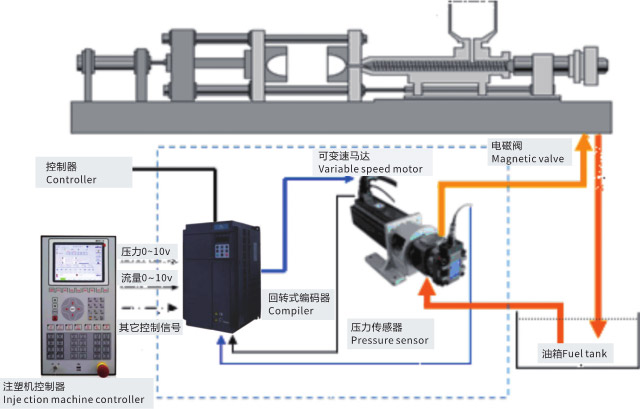

CONTROL SYSTEM

MH9118 control system, dual CPU inndependent processor controller with high efficiency and stable running speed.Machine can connect data with OPCUA、MES etc. management software systems to realize intelligent production.

Abundant SPC quality statistics management, effectively improve productivity.

Servo hydraulic driving technology

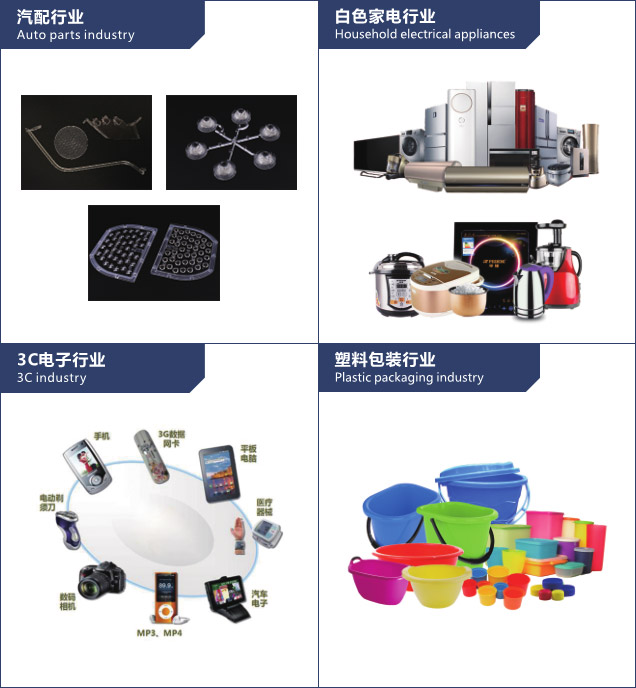

YS series standard injection machine &Product application

TECHNICAL PARAMETERS

| Project | Unit | YS-60 | YS-100 | YS-130 | ||||||||

| Injection unit | INJECTION UNIT | 150 | 250 | 500 | ||||||||

| Screw diameter | mm | Φ24 | Φ26 | Φ30 | Φ30 | Φ35 | Φ40 | Φ35 | Φ40 | Φ45 | ||

| Screw L/D ratio | L/D | 20 | 19 | 18 | 26 | 22 | 20 | 25 | 22 | 20 | ||

| Theoretical injection volume | cm3/sec | 55 | 65 | 86 | 106 | 144 | 188 | 173 | 226 | 286 | ||

| Injection weight(ps) | g | 49 | 58 | 77 | 95 | 129 | 168 | 154 | 202 | 255 | ||

| oz | 1.7 | 2.0 | 2.7 | 3.3 | 4.5 | 5.9 | 5.4 | 7.1 | 9.0 | |||

| Injection pressure | kg/cm2 | 2722 | 2320 | 1742 | 2613 | 1920 | 1740 | 2331 | 1785 | 1410 | ||

| Plasticizing capacity | g/s | 2 | 3 | 4 | 4 | 7 | 10 | 6 | 9 | 12 | ||

| Screw stroke | mm | 122 | 150 | 180 | ||||||||

| Scrwe speed | rpm | 240 | 267 | 225 | ||||||||

| Injection speed | mm/s | 114 | 101 | 94 | ||||||||

| Injection rate | cm3/sec | 51 | 60 | 80 | 71 | 97 | 127 | 90 | 118 | 149 | ||

| Clamping unit | Clamping force | KN | 600 | 1000 | 1300 | |||||||

| Mold opening stroke | mm | 300 | 360 | 410 | ||||||||

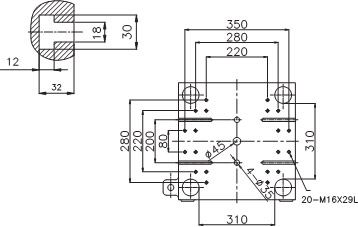

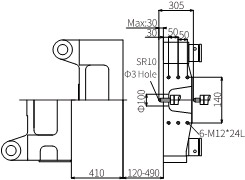

| Mold thickness range | mm | 120-350 | 100-430 | 120-490 | ||||||||

| Mold heght min. | mm | 205*205 | 234*234 | 267*267 | ||||||||

| Tie bar distance | mm | 310*310 | 360*360 | 410*410 | ||||||||

| Ejector stroke | mm | 60 | 100 | 100 | ||||||||

| Ejector force | KN | 27 | 27 | 27 | ||||||||

| Other | Pump motor power | Kw | 9.4 | 12.5 | 15.5 | |||||||

| Temperature control range | (range)set | (0-400℃)*4 | (0-400℃)*4 | (0-400℃)*4 | ||||||||

| Heater power | kw | 3.2 | 6 18 | 7 23 | ||||||||

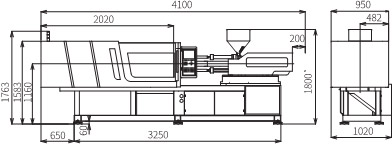

| Machine dimension | mm | 4100*1020*1800 | 4400*1035*1880 | 4917*1139*2026 | ||||||||

| Oil tank | L | 130 | 160 | 160 | ||||||||

| Machine weight | ton | 2.5 | 3.5 | 4.5 | ||||||||

| Max. system pressure | kg/cm2 | 140 | 140 | 140 | ||||||||

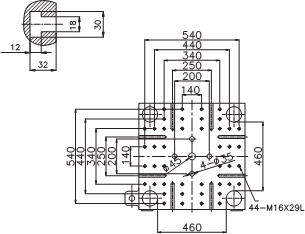

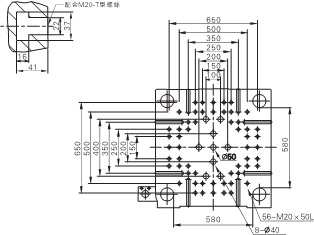

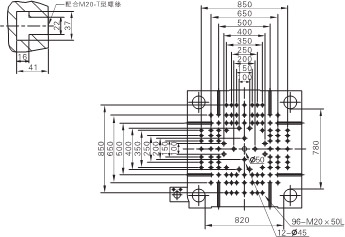

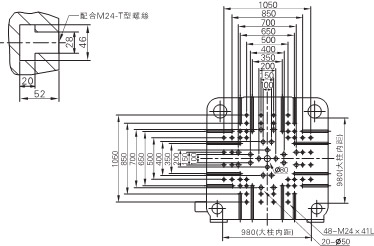

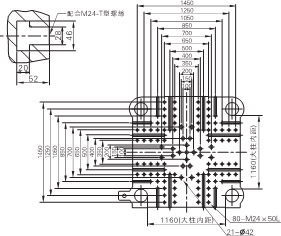

| Platen dimensions |  |

|

|

|||||||||

| Platen dimensions |  |

|

|

|||||||||

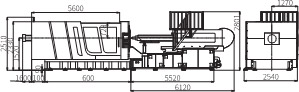

| Machine dimensions |  |

|

|

|||||||||

TECHNICAL PARAMETERS

| Project | Unit | YS-160 | YS-200 | YS-260 | ||||||||

| Injection unit | INJECTION UNIT | 600 | 800 | 1100 | ||||||||

| Screw diameter | mm | Φ40 | Φ45 | Φ50 | Φ40 | Φ50 | Φ55 | Φ50 | Φ55 | Φ60 | ||

| Screw L/D ratio | L/D | 24 | 21 |

19 |

23 | 21 | 19 | 24 | 22 | 20 | ||

| Theoretical injection volume | cm3/sec | 274 | 347 | 428 | 358 | 442 | 534 | 471 | 570 | 678 | ||

| Injection weight(ps) | g | 244 | 309 | 382 | 319 | 394 | 477 | 420 | 509 | 605 | ||

| oz | 8.6 | 10.9 | 13.5 | 11.3 | 13.9 | 16.8 | 14.8 | 17.9 | 21.4 | |||

| Injection pressure | kg/cm2 | 2205 | 1742 | 1411 | 2333 | 1890 | 1562 | 2394 | 1979 | 1663 | ||

| Plasticizing capacity | g/s | 7 | 10 | 14 | 10 | 14 | 18 | 14 | 18 | 24 | ||

| Screw stroke | mm | 218 | 225 | 240 | ||||||||

| Scrwe speed | rpm | 189 | 180 | 180 | ||||||||

| Injection speed | mm/s | 96 | 91 | 89 | ||||||||

| Injection rate | cm3/sec | 120 | 152 | 188 | 144 | 178 | 215 | 175 | 212 | 253 | ||

| Clamping unit | Clamping force | KN | 1600 | 2000 | 2600 | |||||||

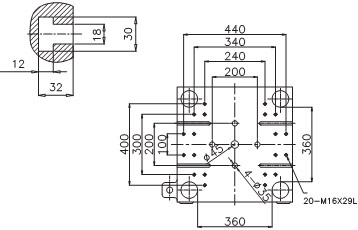

| Mold opening stroke | mm | 450 | 510 | 540 | ||||||||

| Mold thickness range | mm | 160-550 | 160-610 | 160-670 | ||||||||

| Mold heght min. | mm | 299*299 | 332*332 | 380*380 | ||||||||

| Tie bar distance | mm | 460*460 | 510*510 | 580*580 | ||||||||

| Ejector stroke | mm | 110 | 130 | 150 | ||||||||

| Ejector force | KN | 40 | 40 | 54 | ||||||||

| Other | Pump motor power | Kw | 18.7 | 25.8 | 28.8 | |||||||

| Temperature control range | (range)set | (0-400℃)*4 | (0-400℃)*4 | (0-400℃)*4 | ||||||||

| Heater power | kw | 8.42 | 11.75 | 15 | ||||||||

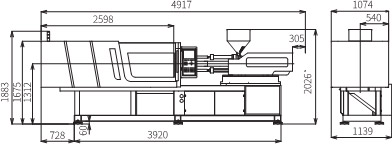

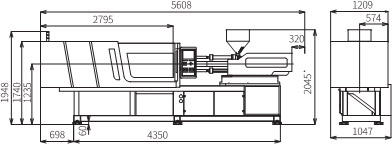

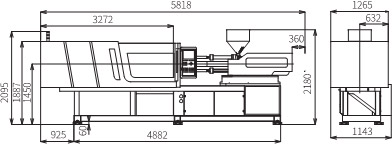

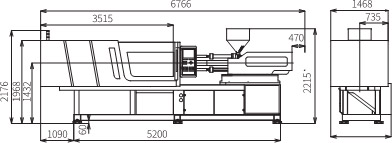

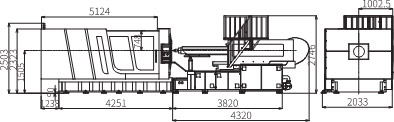

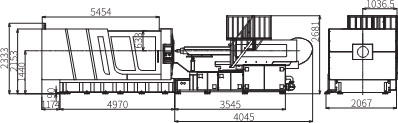

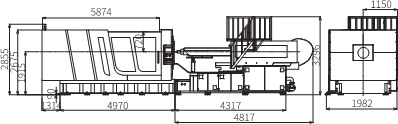

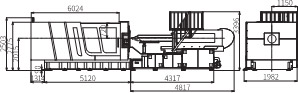

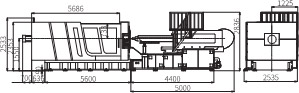

| Machine dimension | mm | 5608*1047*2045 | 5818*1143*2180 | 6766*1145*2215 | ||||||||

| Oil tank | L | 200 | 320 | 400 | ||||||||

| Machine weight | ton | 5.5 | 7.5 | 11 | ||||||||

| Max. system pressure | kg/cm2 | 140 | 140 | 140 | ||||||||

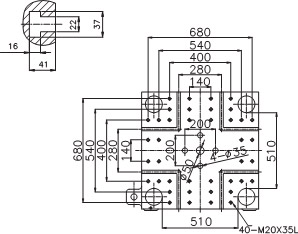

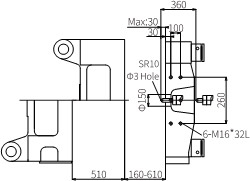

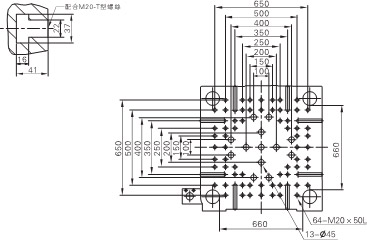

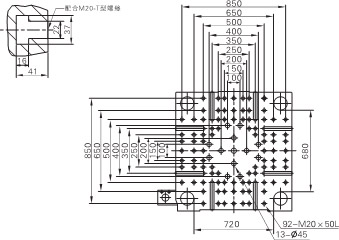

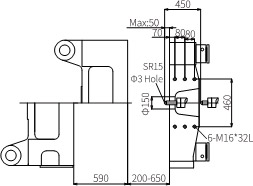

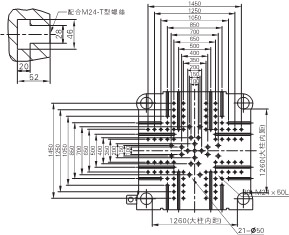

| Platen dimensions |  |

|

|

|||||||||

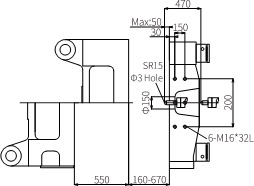

| Platen dimensions |  |

|

|

|||||||||

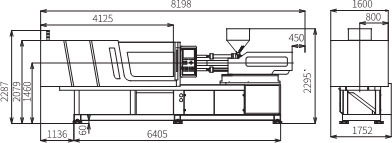

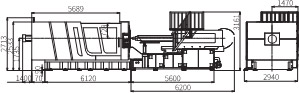

| Machine dimensions |  |

|

|

|||||||||

TECHNICAL PARAMETERS

| Project | Unit | YS-320 | YS-380 | YS-470 | ||||||||

| Injection unit | INJECTION UNIT | 1700 | 2200 | 3000 | ||||||||

| Screw diameter | mm | Φ60 | Φ65 | Φ70 | Φ65 | Φ70 | Φ75 | Φ75 | Φ80 | Φ85 | ||

| Screw L/D ratio | L/D | 23 | 21 | 19 | 23 | 22 | 20 | 22 | 21 | 19 | ||

| Theoretical injection volume | cm3/sec | 791 | 929 | 1077 | 1015 | 1177 | 1351 | 1501 | 1708 | 1928 | ||

| Injection weight(ps) | g | 706 | 829 | 961 | 906 | 1050 | 1206 | 1340 | 1525 | 2131 | ||

| oz | 24.9 | 29.3 | 33.9 | 32.0 | 37.1 | 42.5 | 47.3 | 53.8 | 75.2 | |||

| Injection pressure | kg/cm2 | 2191 | 1867 | 1610 | 2195 | 1893 | 1649 | 2050 | 1801 | 1596 | ||

| Plasticizing capacity | g/s | 27 | 34 | 43 | 27 | 33 | 41 | 39 | 47 | 56 | ||

| Screw stroke | mm | 280 | 306 | 340 | ||||||||

| Scrwe speed | rpm | 205 | 106 | 150 | ||||||||

| Injection speed | mm/s | 85 | 92 | 93 | ||||||||

| Injection rate | cm3/sec | 240 | 281 | 326 | 306 | 355 | 408 | 410 | 466 | 526 | ||

| Clamping unit | Clamping force | KN | 3200 | 3800 | 4700 | |||||||

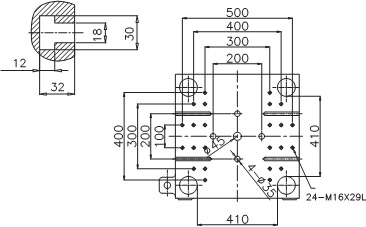

| Mold opening stroke | mm | 590 | 645 | 730 | ||||||||

| Mold thickness range | mm | 200-650 | 190-790 | 250-800 | ||||||||

| Mold heght min. | mm | 397*397 | 470*440 | 530*510 | ||||||||

| Tie bar distance | mm | 660*660 | 720*680 | 820*780 | ||||||||

| Ejector stroke | mm | 185 | 200 | 200 | ||||||||

| Ejector force | KN | 79 | 79 | 99 | ||||||||

| Other | Pump motor power | Kw | 37 | 47.2 | 28.8+28.8 | |||||||

| Temperature control range | (range)set | (0-400℃)*4 | (0-400℃)*4 | (0-400℃)*4 | ||||||||

| Heater power | kw | 15 | 21 | 27.22 | ||||||||

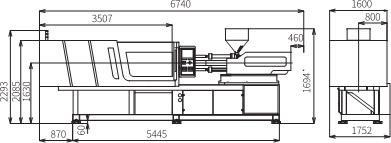

| Machine dimension | mm | 6740*1752*1604 | 8198*1752*2295 | 8300*1976*2405 | ||||||||

| Oil tank | L | 450 | 620 | 940 | ||||||||

| Machine weight | ton | 12 | 14 | 18.5 | ||||||||

| Max. system pressure | kg/cm2 | 140 | 140 | 140 | ||||||||

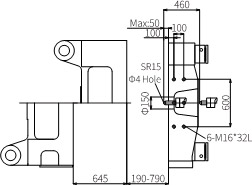

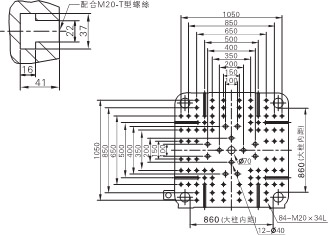

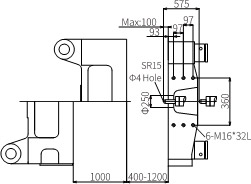

| Platen dimensions |  |

|

|

|||||||||

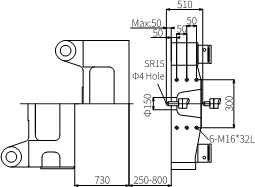

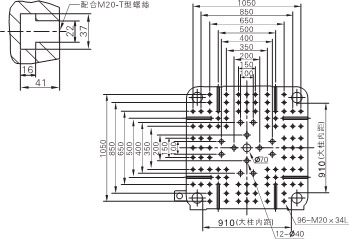

| Platen dimensions |  |

|

|

|||||||||

| Machine dimensions |  |

|

|

|||||||||

TECHNICAL PARAMETERS

| Project | Unit | YS-550 | YS-650 | YS-750 | |||||||||||

| Injection unit | INJECTION UNIT | 5100 | 5900 | 7400 | |||||||||||

| Screw diameter | mm | Φ80 | Φ85 | Φ90 | Φ95 | Φ85 | Φ90 | Φ95 | Φ100 | Φ90 | Φ95 | Φ100 | Φ110 | ||

| Screw L/D ratio | L/D | 24 | 23 | 22 | 21 | 23 | 22 | 21 | 20 | 22 | 21 | 20 | 18 | ||

| Theoretical injection volume | cm3/sec | 2165 | 2444 | 2741 | 3053 | 2552 | 2861 | 3188 | 3533 | 2988 | 3330 | 3690 | 4464 | ||

| Injection weight(ps) | g | 1933 | 2182 | 2446 | 2725 | 2278 | 2554 | 2845 | 3153 | 2667 | 2972 | 3293 | 3984 | ||

| oz | 68.2 | 77.0 | 86.3 | 96.1 | 80.3 | 90.1 | 100.4 | 111.2 | 94.1 | 104.8 | 116.2 | 140.5 | |||

| Injection pressure | kg/cm2 | 2380 | 2108 | 1880 | 1688 | 2329 | 2078 | 1865 | 1683 | 2498 | 2242 | 2023 | 1672 | ||

| Plasticizing capacity | g/s | 47 | 57 | 68 | 79 | 60 | 71 | 84 | 98 | 76 | 89 | 104 | 139 | ||

| Screw stroke | mm | 431 | 450 | 470 | |||||||||||

| Scrwe speed | rpm | 152 | 160 | 170.8 | |||||||||||

| Injection speed | mm/s | 90 | 86 | 76 | |||||||||||

| Injection rate | cm3/sec | 452 | 511 | 573 | 638 | 487 | 545 | 608 | 673 | 484 | 540 | 598 | 724 | ||

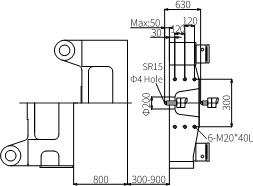

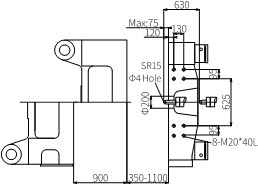

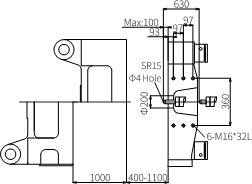

| Clamping unit | Clamping force | KN | 5500 | 6500 | 7500 | ||||||||||

| Mold opening stroke | mm | 800 | 900 | 1000 | |||||||||||

| Mold thickness range | mm | 300-900 | 350-1100 | 400-1100 | |||||||||||

| Mold heght min. | mm | 525*525 | 560*560 | 626*626 | |||||||||||

| Tie bar distance | mm | 860*860 | 910*910 | 980*980 | |||||||||||

| Ejector stroke | mm | 220 | 220 | 240 | |||||||||||

| Ejector force | KN | 161 | 226 | 209 | |||||||||||

| Other | Pump motor power | Kw | 28.8+37 | 28.8+37 | 37+37 | ||||||||||

| Temperature control range | (range)set | (0-400℃)*4 | (0-400℃)*4 | (0-400℃)*4 | |||||||||||

| Heater power | kw | 3 15 | 34.25 | 40.73 | |||||||||||

| Machine dimension | mm | 9809*2033*2746 | 10189*2067*2681 | 11101*1982*3296 | |||||||||||

| Oil tank | L | 1000 | 1200 | 1400 | |||||||||||

| Machine weight | ton | 24 | 29 | 40 | |||||||||||

| Max. system pressure | kg/cm2 | 170 | 170 | 170 | |||||||||||

| Platen dimensions |  |

|

|

||||||||||||

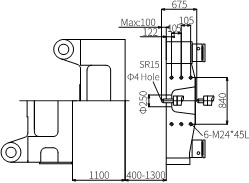

| Platen dimensions |  |

|

|

||||||||||||

| Machine dimensions |  |

|

|

||||||||||||

TECHNICAL PARAMETERS

| Project | Unit | YS-850 | YS-1000 | YS-1250 | YS-1480 | ||||||||||||||

| Injection unit | INJECTION UNIT | 9800 | 11000 | 11000 | 25000 | ||||||||||||||

| Screw diameter | mm | Φ95 | Φ100 | Φ110 | Φ120 | Φ100 | Φ110 | Φ120 | Φ130 | Φ100 | Φ120 | Φ130 | Φ140 | Φ130 | Φ140 | Φ150 | Φ160 | ||

| Screw L/D ratio | L/D | 23 | 22 | 20 | 18 | 23 | 21 | 19 | 18 | 21 | 19 | 18 | 17 | 23 | 21 | 20 | 19 | ||

| Theoretical injection volume | cm3/sec | 3684 | 4082 | 4939 | 5878 | 4318 | 5224 | 6217 | 7297 | 5224 | 6217 | 7297 | 8462 | 10746 | 12463 | 14307 | 16278 | ||

| Injection weight(ps) | g | 3288 | 3643 | 4408 | 5246 | 3853 | 4663 | 5549 | 6512 | 4663 | 5549 | 6512 | 7553 | 9591 | 11123 | 12769 | 14528 | ||

| oz | 116.0 | 128.5 | 155.5 | 185.1 | 135.9 | 164.5 | 195.7 | 229.7 | 164.5 | 195.7 | 229.7 | 266.4 | 338.3 | 392.3 | 450.4 | 512.4 | |||

| Injection pressure | kg/cm2 | 2670 | 2410 | 1992 | 1673 | 2570 | 2124 | 1785 | 1521 | 2124 | 1785 | 1521 | 1311 | 2390 | 2061 | 1795 | 1578 | ||

| Plasticizing capacity | g/s | 97 | 113 | 151 | 196 | 110 | 146 | 190 | 241 | 155 |

202 |

256 | 320 | 189 | 236 | 290 | 352 | ||

| Screw stroke | mm | 520 | 550 | 550 | 810 | ||||||||||||||

| Scrwe speed | rpm | 186 | 180 | 191 | 141 | ||||||||||||||

| Injection speed | mm/s | 86 | 88 | 94 | 86 | ||||||||||||||

| Injection rate | cm3/sec | 611 | 677 | 724 | 975 | 694 | 840 | 1000 | 1174 | 894 | 1063 | 1248 | 1448 | 1138 | 1320 | 1515 | 1724 | ||

| Clamping unit | Clamping force | KN | 8500 | 10000 | 12500 | 14200 | |||||||||||||

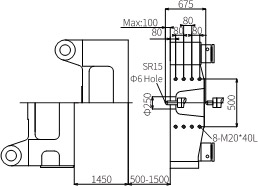

| Mold opening stroke | mm | 1000 | 1100 | 1275 | 1450 | ||||||||||||||

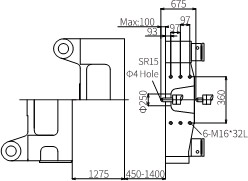

| Mold thickness range | mm | 400-1200 | 400-1300 | 450-1400 | 500-1500 | ||||||||||||||

| Mold heght min. | mm | 625*625 | 690*690 | 790*790 | 845*845 | ||||||||||||||

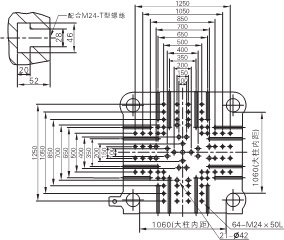

| Tie bar distance | mm | 1060*1060 | 1160*1160 | 1260*1260 | 1320*1320 | ||||||||||||||

| Ejector stroke | mm | 240 | 300 | 320 | 340 | ||||||||||||||

| Ejector force | KN | 209 | 262 | 262 | 300 | ||||||||||||||

| Other | Pump motor power | Kw |

37+28.8+28.8 |

37+37+28.8 | 37+37+37 | 42+42+31.4 | |||||||||||||

| Temperature control range | (range)set | (0-400℃)*4 | (0-400℃)*4 | (0-400℃)*4 | (0-400℃)*4 | ||||||||||||||

| Heater power | kw | 46.48 | 51.2 | 62.78 | 76.13 | ||||||||||||||

| Machine dimension | mm | 11251*1982*3396 | 11936*2535*2826 | 12820*2535*2801 | 14420*2940*3161 | ||||||||||||||

| Oil tank | L | 1600 | 1700 | 1700 | 2500 | ||||||||||||||

| Machine weight | ton | 42 | 50.8 | 74 | 84 | ||||||||||||||

| Max. system pressure | kg/cm2 | 170 | 170 | 170 | 170 | ||||||||||||||

| Platen dimensions |  |

|

|

|

|||||||||||||||

| Platen dimensions |  |

|

|

|

|||||||||||||||

| Machine dimensions |  |

|

|

|

|||||||||||||||

YS Series Configuration

| YS Series Configuration | |

| Optional | |

| Clamping Unit | |

| Precision clamping Transducer / ejecting Transducer /injection Transducer | ● |

| Platens and toggles using QT500-7A material | ● |

| Reserved thread hole for robot | ● |

| Hydraulic drive gear for mold adjustment | ● |

| Hydraulic and electrical safety protection | ● |

| Wearable manganese steel rail below movable platen | ● |

| Automatic centralized lubrication system | ● |

| Multi ejection funtions | ● |

| Low pressure mold protection | ● |

| T-slot & mounting hole platen | ● |

| Automatic mold thickness adjustment | ● |

| Ejector backward reset function | ● |

| Anti - jamming Buffer Strip on safety door | ● |

| Machine cover on clamping unit fulll closed protection( top cover for machines lower than 2m) | ● |

| Mechanical safety lock | ○ |

| Special mold mounting holes | ○ |

| Mold hanger (Max 200T) | ○ |

| Mold insulation board | ○ |

| Enlarged ejector force and ejector stroke | ○ |

| Enlarged Max. mold height | ○ |

| Magnetic Platen | ○ |

| Ejector backward confirmation funciton | ○ |

| Change the fixed plate mould positioning ring | ○ |

| Protective baffle between machine base and movable door | ○ |

| Injection Unit | |

| Double injection cylinders | ● |

| Low speed high torque hydraulic motor | ● |

| Nitriding alloy steel screw & barrel | ● |

| Cooling device on hopper feeding area | ● |

| Nozzle and barrel multi-section PID temperature control | ● |

| Double carriage movement cylinders | ● |

| Semi enclosed insulation barrel cover, nozzle protection cover | ● |

| Anti-cold start screw protection | ● |

| Automatic purge function | ● |

| Nozzle back and forth movable before and after plasticizing | ● |

| Hopper sliding or scrolling unit(60-450T) | ● |

| Screw speed detection | ● |

| Ceramic heater | ○ |

| High speed low torque hydraulic motor | ○ |

| Special screw and barrel(Electroplating, alloy, PC, PMMA, PBT, PA,etc) | ○ |

| Fan for cooling barrel | ○ |

| Spring self-locking nozzle | ○ |

| Increase/decrease injection stroke, or screw & barel size | ○ |

| Rotating injection unit | ○ |

| Infrared heater | ○ |

| Position Transducer control on Injection unit | ○ |

| Manual centralized grease lubrication pump on injection unit (>550T) | ● |

| Manual centralized grease lubrication pump on injection unit (<550T) | ○ |

| Stainless steel hopper | ○ |

| Hopper rail (>450T) | ○ |

| Hopper rail (<450T) | ● |

| protection device on hopper feeding area | ○ |

| Hydraulic system | |

| Third generation servo pump system | ● |

| High precision real-time bypass filter device | ○ |

| Low noise energy saving hydraulic circuit | ● |

| Brand hydraulic valve | ● |

| Brand hydraulic seal | ● |

| Differential fast mold clamping oil circuit (>200T) | ● |

| Built-in cooler ( <450T ) | ● |

| Mold openning brake oil circuit(mold open back pressure) | ● |

| Automatic detection of oil temperature/high and low temperature alarm | ● |

| Exposed high pressure tubing with explosion - proof chain | ● |

| 1 set hydraulic core pull with valve(2 sets for 550T and above ) | ● |

| multi-sect water distruibutor with fast plug | ● |

| Plasticizing proportional back pressure control (> 550T) | ○ |

| Increase multi-stage oil pumps and motors | ○ |

| upgrading plasticizing motor sizes | ○ |

| Synchronous ejection, core pulling, and plasticizing | ○ |

| High response energy storage servo injection system | ○ |

| Multiple core-pulling devices | ○ |

| Hydraulic rotary demoulding device | ○ |

| Glass tube cooling flow meter | ○ |

| Hydraulic oil position sensor | ○ |

| Hydraulic safety valve with position feedback | ○ |

| Hydraulic safety cam valve | ● |

| Electrical Unit | |

| Forced protection of barrel heating | ● |

| Input and output view screen | ● |

| Automatic heat preservation and automatic heating setting function | ● |

| Injection pressure holding mode: time/position/time+position | ● |

| 10-inch TFT LCD display (>550T) | ● |

| 8-inch TFT LCD display (<550T) | ● |

| 240 groups of large-capacity process parameter storage, USB port | ● |

| Multiple languages | ● |

| Multi-level password protection , operation panel with lock button key | ● |

| Emergency Stop protection of front and rear safety doors | ● |

| Quality data process control interface | ● |

| Production process control (SPC) real-time list interface | ● |

| Reserve a variety of interfaces such as air blowing, pull back protection, etc. (with software, without hardware) | ● |

| Two sets of AC380V/16A three-phase sockets, one set of AC220V/10A multi-function two or three plug sockets | ● |

| Hot runner mould needle valve control | ○ |

| China standard Robot electrical interface | ○ |

| European standard 67 Robot electrical interface | ○ |

| European standard 12 Robot electrical interface | ○ |

| Electric safety door (>550T) | ● |

| Two-color warning lights | ● |

| Hot runner mold interface | ○ |

| Air-operated sequence valve | ○ |

| Electric rotating demoulding interface | ○ |

| Adjustable power supply voltage | ○ |

| A set of blowing valve device | ○ |

| Sets blowing valve device | ○ |

| Gas-assisted injection device | ○ |

| Central (networked) monitoring system | ○ |

| Infrared Grating protection in front and rear safety doors (>550T) | ○ |

| Energy consumption display | ○ |

| Electric meter | ○ |

| electrically heated coil with Solid State Relay | ● |

| Computer system with European brand | ○ |

| Direct temperature control for ejection nozzle | ○ |

| Rear safety door operation (customer commitment to safety responsibility) | ○ |

| The front safety door closes in place and confirms on the screen | ○ |

| Main power with Air switch | ● |

| Electric heating master control with AC contactor | ● |

| Isolation transformer | ○ |

| Others | |

| Manual | ● |

| Suspension feet | ● |

| Toolbox and tools | ● |

| Mould clamps | ● |

| Special wrench for Nozzle | ● |

| Hydraulic oil | ○ |

| Dryer | ○ |

| Automatic feeding machine | ○ |

| Remarks: ● means the function is standard; ○ means the function is optional; | |

HORIZONTAL BAKELITE SPECIAL INJECTION MOLDING MACHINE

PRODUCT APPLICATION:Be used for a variety of thermosetting (Bakelite materia) Bakelite, Tableware, Hand wheel, Bakelite handle, cutlery, panhandle, Pot ears, Knife handle, Bakelite knob, Switch, Oven accessories, Terminals, End button, Meter accessories, Meter shell and etc.

SPECIALIZED INJECTION MOIDING MACHINE FOR FRUIT FRAME

PRODUCT CHARACTERISTICS:

1. Reinforce the Energy-Saving servo Motor system;

2. The Platen, Tie bar and Main parts adopt new design of hardening analysis;

3. Adopt specialized computer controller, machine can run fast and stably, which is 10%-20% faster than the common fruit frame machine of the same type in the market;

4. The lubrication system adopts point-to-point quantitative lubrication system to ensure that every point of lubricated in properly supplied;

5. Adopt specialized Bi-metallic alloy screw for fruit frame machine to extend the service life of screw.

TECHNICAL PARAMETERS

| Project | 单位Unit | YS-130B | YS-160B | YS-200B | YS-300B | |||||

| Injection unit | Screw diameter | mm | Φ36 | Φ40 | Φ40 | Φ44 | Φ44 | Φ50 | Φ68 | Φ75 |

| Theoretical injection volume | cm3 | 163 | 226 | 274 | 331 | 342 | 442 | 1111 | 1351 | |

| Injection volume | gram | 180 | 250 | 303 | 366 | 378 | 488 | 1227 | 1492 | |

| ozs | 4.3 | 5.9 | 8.6 | 10.4 | 10.8 | 13.9 | 35.0 | 42.5 | ||

| Injection pressure | kg/cm2 | 2035 | 1470 | 2205 | 1822 | 2440 | 1890 | 2006 | 1648 | |

| Injection speed | mm/s | 88 | 84 | 90 | 80 | |||||

| Injection rate | cm2/sec | 92 | 127 | 106 | 128 | 145 | 188 | 291 | 354 | |

| Clamping unit | Closing force | metrictons | 128 | 160 | 200 | 300 | ||||

| Clamping stroke | mm | 410 | 450 | 510 | 590 | |||||

| Mold thickness | mm | 120-490 | 160-550 | 160-610 | 200-650 | |||||

| Recommended minimum mold size | mm | 267*367 | 299*299 | 332*332 | 397*397 | |||||

| Big column inner distance | mm | 410*410 | 460*460 | 510*510 | 660*660 | |||||

| Die size | mm | 600*600 | 670*670 | 745*745 | 894*894 | |||||

| Pallet stroke | mm | 100 | 110 | 130 | 185 | |||||

| Electrical Equipment | Electric motor | Kw | 14.1 | 16.5 | 21.2 | 31.4 | ||||

| Temperature control range | (range)set | (0-400℃)*4 | (0-400℃)*4 | (0-400℃)*4 | (0-400℃)*4 | |||||

| Electric heating capacity | Kw | 8.88 | 11.45 | 14.4 | 19.75 | |||||

| Other | Mechanical dimensions(LxWxH) | mm | 5000*1050*1790 | 5555*1100*1790 | 6080*1250*1860 | 7340*1430*2100 | ||||

| Oil tank | liter | 210 | 250 | 340 | 450 | |||||

| Machine weight | metrictons | 4.5 | 5.5 | 7.5 | 12 | |||||

| Maximum system pressure | kg/cm2 | 140 | 140 | 140 | 140 | |||||

TECHNICAL PARAMETERS

| Project | 单位Unit | YS-320K | YS-380K | YS-470K | YS-550K | |

| Injection unit | Screw diameter | mm | Φ65 | Φ75 | Φ85 | Φ95 |

| Theoretical injection volume | cm3 | 929 | 1351 | 1928 | 3053 | |

| Injection volume | gram | 829 | 1206 | 1721 | 2725 | |

| ozs | 29.2 | 42.5 | 60.7 | 96.1 | ||

| Injection pressure | kg/cm2 | 1417 | 1648 | 1770 | 1535 | |

| Injection speed | mm/s | 106 | 103 | 105 | 107 | |

| Injection rate | cm2/sec | 350 | 453 | 593 | 760 | |

| Clamping unit | Closing force | metrictons | 300 | 380 | 470 | 550 |

| Clamping stroke | mm | 590 | 645 | 730 | 800 | |

| Mold thickness | mm | 200-650 | 190-790 | 250-800 | 350-900 | |

| Recommended minimum mold size | mm | 397*397 | 425*415 | 475*475 | 525*525 | |

| Big column inner distance | mm | 660*660 | 710*690 | 760*760 | 860*860 | |

| Die size | mm | 894*894 | 1000*980 | 1120*1120 | 1250*1250 | |

| Pallet stroke | mm | 185 | 200 | 200 | 220 | |

| Electrical Equipment | Electric motor | Kw | 31.4 | 31.4 | 42.4 | 30+30 |

| Temperature control range | (range)set | (0-400℃)*4 | (0-400℃)*4 | (0-400℃)*4 | (0-400℃)*4 | |

| Electric heating capacity | Kw | 19.75 | 23.05 | 23.05 | 27.7 | |

| Other | Mechanical dimensions(LxWxH) | mm | 7340*1430*2100 | 8020*1500*2175 | 8340*1920*2210 | 9350*1950*2220 |

| Oil tank | liter | 450 | 620 | 780 | 1000 | |

| Machine weight | metrictons | 12 | 14 | 18.5 | 24 | |

| Maximum system pressure | kg/cm2 | 140 | 140 | 140 | 140 | |

Note: The output of this product parameter is calculated according to the specific gravity of polystyrene of 1.05, assuming an efficiency of 0.88. As the product is continuously researched and improved, the design changes are subject to change without notice.

Next: Last pagePrevious: Servo energy injection molding machine